Did you know that inefficient thermal management can reduce the lifespan of electronic devices by up to 50%? Thermally conductive encapsulants are an advanced solution for dissipating heat and protecting electronic components.

In the rapidly evolving landscape of advanced electronics and industrial engineering, thermal management has become a crucial challenge for designers and manufacturers. With components becoming increasingly compact and powerful, efficient heat dissipation is essential to ensure high performance and long-term reliability.

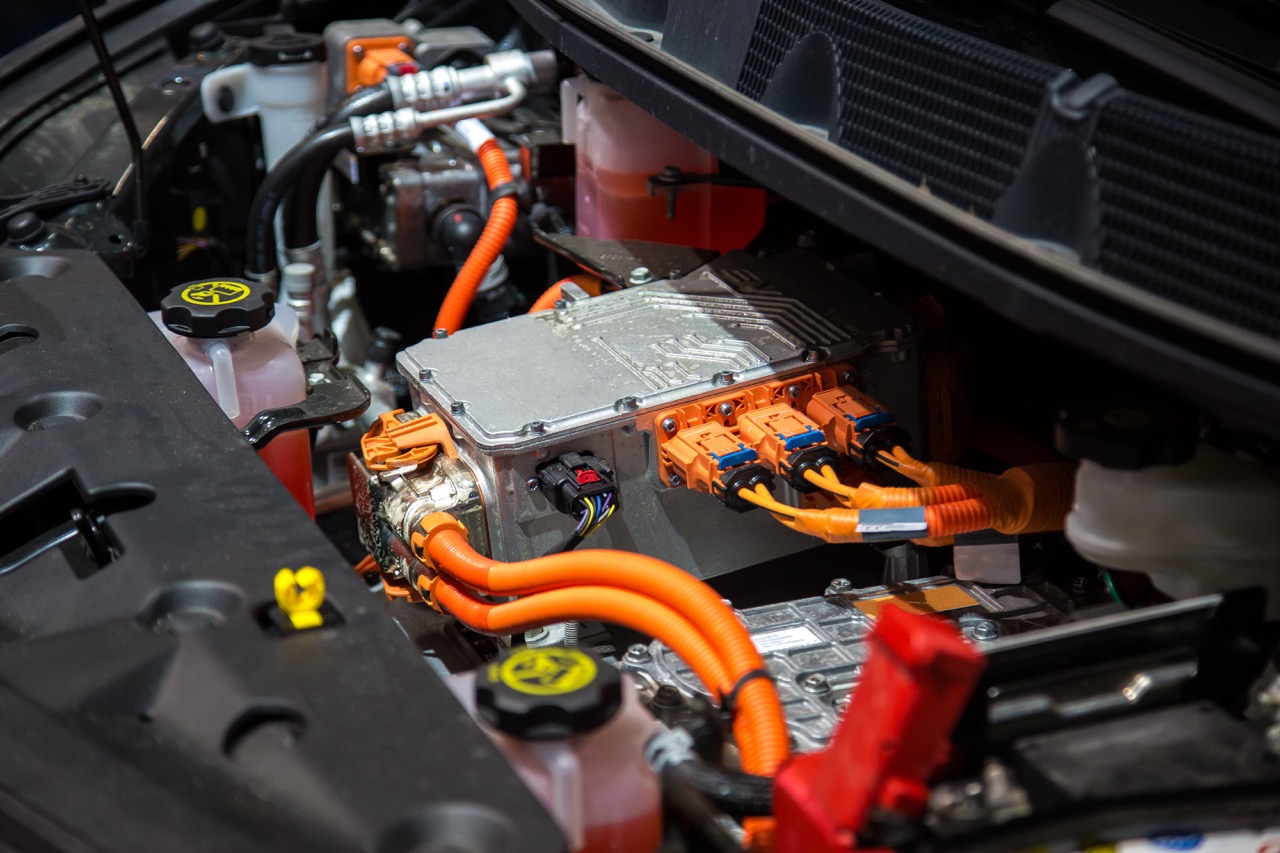

Thermally conductive encapsulants are advanced materials designed to enhance heat dissipation and protect electronic components from environmental stress. Thanks to their high thermal conductivity, they ensure efficient cooling while offering electronic protection and resistance to extreme conditions. Widely used in industries such as automotive, renewable energy, industrial electronics, and aerospace, these materials play a crucial role in ensuring the reliability and longevity of electronic systems.

MD Poland provides a range of Dowsil products specifically developed to optimize thermal management, offering customized solutions for various applications. Choosing the right encapsulant requires analyzing thermal dissipation needs and operating conditions to ensure optimal performance and durability.

What are thermally conductive encapsulants

Thermally conductive encapsulants are an advanced class of thermally conductive materials designed to meet the thermal management needs of modern electronic systems. These innovative, fluid materials are ideal for automated high-volume production, offering a lightweight and flexible alternative to pre-cured thermal interface materials.

Unlike other thermal management solutions, encapsulants combine thermal conductivity and advanced protection. These are special compounds based on silicone, applied with precision to electronic circuits to improve heat transfer and protect sensitive components from environmental stress.

Advantages of thermally conductive encapsulants

The advantages of these products and thermally conductive materials go beyond simple heat dissipation:

- Low viscosity: facilitates application on complex geometries, optimising production processes and guaranteeing uniform coverage.

- Dual functionality: they offer effective heat dissipation combined with advanced mechanical protection, increasing the life of electronic components.

- Resistance to extreme conditions: they operate between -40 °C and 200 °C, with excellent resistance to humidity, oxidation and thermal shock.

Application without primer: many modern formulations guarantee effective adhesion without primer, reducing production time and costs.

Sectors in which thermally conductive encapsulants are used

Thanks to their versatility, thermally conductive encapsulants are widely used in high-tech sectors, including:

- In the automotive industry and in electric vehicles, these materials are essential for:

- Inverters

- Electronic control units (ECU)

- On-board battery chargers (OBC)

- Battery management systems

In solar energy systems they are used for:

- Protection of photovoltaic panels

- Thermal management of power inverters

- Ensuring stable performance in varying climatic conditions

In critical power modules, these materials offer:

- Efficient thermal management

- Increased operational reliability

- Protection against environmental degradation

Aerospace

For the aerospace industry, thermally conductive encapsulants are essential for:

- Avionics systems

- Satellite components

- Communication equipment

Advanced solutions for thermal efficiency in electronic devices

MD Poland is a point of reference in the supply of thermally conductive insulating materials, offering customised solutions for the electronics, automotive and aerospace industries. We offer a wide range of products designed to improve heat dissipation, guaranteeing reliability and durability for electronic devices.

Choosing the right thermal encapsulant is essential to ensure optimal thermal management and prevent overheating of electronic components, thus avoiding performance drops or premature failures. For this reason, MD Poland provides qualified technical support, helping companies identify the solution that best suits their application needs.

On our website you can find the following thermal encapsulants:

- DOWSIL™ TC-6011 → Optimised for light projects, it offers exceptional fluidity and thermal conductivity.

- DOWSIL™ TC-6020 → Designed for high-power systems with higher dissipation requirements.

- DOWSIL™ EI-2888 → A primerless silicone encapsulant designed for sensitive electronic applications, offering high transparency and protection against environmental agents.

- DOWSIL™ CN-8760 → A thermally conductive encapsulant ideal for devices requiring efficient heat dissipation, combining thermal conductivity and mechanical flexibility.

- DOWSIL™ EE-3200 → Low-voltage silicone encapsulant to reduce stress on electronic components, ensuring reliable protection and long operating life.

Thanks to a wide range of thermally conductive adhesives, thermal management solutions and specific materials for the thermal interface, MD Poland helps companies and designers improve the thermal efficiency of their devices.

To find out more about thermally conductive encapsulants, contact the MD Poland experts and find the ideal product for your applications.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.