Wyzwania związane z e-mobilnością w systemach e-drive

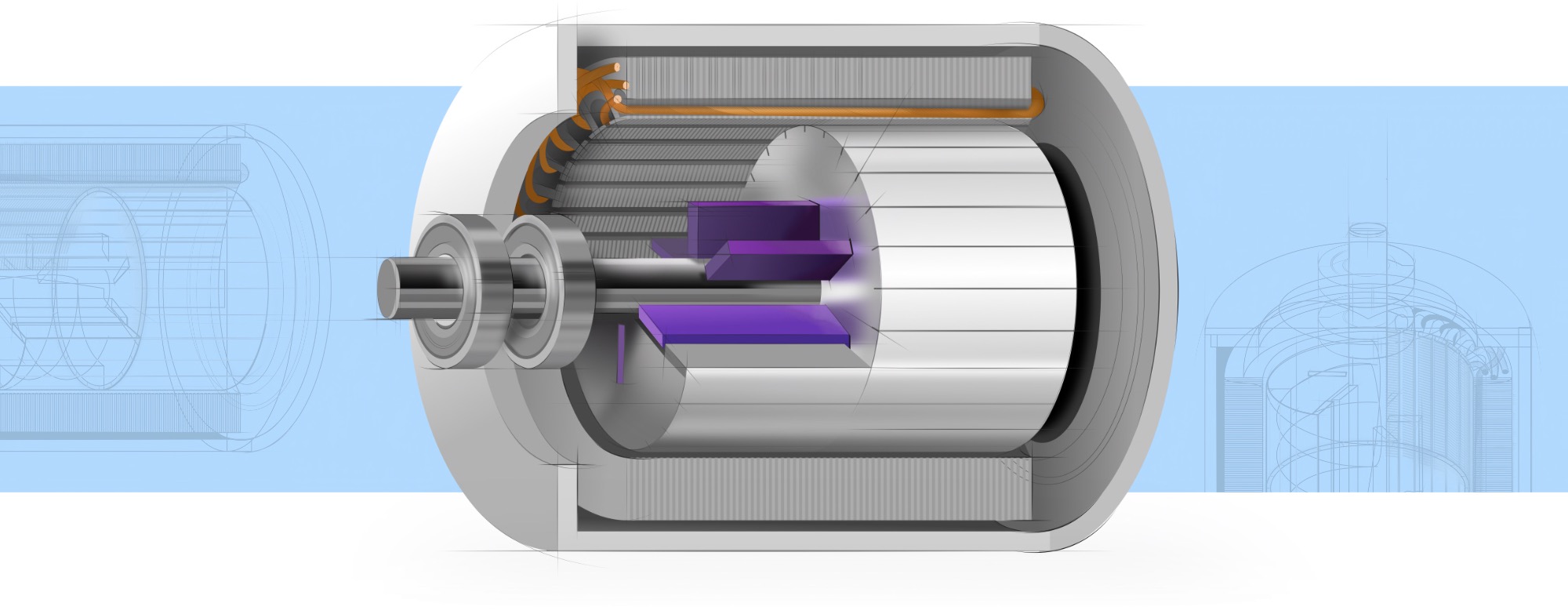

Elektryczne systemy napędowe składają się z silnika elektrycznego, przekładni oraz obudowy, które jako całość są odpowiedzialne za prędkość oraz obroty w najlepszych pojazdach elektrycznych dzisiaj. Systemy napędu elektrycznego wymagają specyficznych technologii klejenia, zaprojektowanych tak, aby do systemu nie dostawał się kurz, płyny oraz inne czynniki środowiskowe, które mają wpływ na bezpieczną i wydajną jazdę pojazdu.

Najnowocześniejsze technologie zaproponowane przez firmę MD Polonia zostały stworzone w celu zaspokojenia i wyprzedzenia pojawiających się potrzeb u producentów elektrycznych i hybrydowych układów napędowych. MD Polonia wspiera producentów pojazdów elektrycznych na każdym etapie, od projektowania aż po produkcję, w celu optymalizacji materiałów niezbędnych do sprostania wymaganiom dotyczących komponentów w systemach e-drive:

- Smary do łożysk w silnikach elektrycznych

- Thermal potting

- Magnet bonding

- Gasketing

Zarządzanie temperaturą

Obecne trendy w branży zmierzają do łączenia silników elektrycznych z systemami konwersji energii, jednocześnie minimalizując komponenty, co pozwala producentom zaoszczędzić miejsce i zmniejszyć ich wagę. Wiąże się to z większą mocą oraz zwiększeniem ryzyka awarii silnika. W celu zmniejszenia tych zagrożeń, w produkcji silników, niezbędne jest użycie lepszych materiałów do regulowania ciepła, w tym żywic o wyższej przewodności cieplnej.

Niezawodność

Żywotność e-drive silników elektrycznych jest poważnym wyzwaniem dla producentów. Nieustanny ruch oraz tendencja do zwiększania mocy wymagają najmocniejszych materiałów. Technologie hermetyzacji i uszczelniania termicznego firmy MD Polonia, mogę pomóc w zwiększeniu niezawodności elektrycznych systemów napędowych.

Magnet bonding

Kleje strukturalne Araldite są dedykowane do trzech faz montażu silników elektrycznych:

- montaż magnesów i stosów do laminowania,

- zespół wału i wirnika

- montaż stojana i obudowy.

-

Smary do silników elektrycznych

- Smar plastyczny jest kluczowym składnikiem, ponieważ pozwala na zachowanie precyzji, wyciszenia i prostoty wykonania za pomocą niewielkich kosztów. Stosując smar plastyczny, poszczególne części silnika są od siebie oddzielone tym właśnie cienką powłoką, co przyczynia się do zmniejszenia hałasu silnika oraz spowalnia zużycie jego części.

-

-

Thermal potting

- Enkapsulanty mają za zadanie chronić delikatne elementy elektroniczne w silniku elektrycznym przed wibracjami, wysokimi temperaturami, kurzem, korozją i wilgocią.

Gasketing

-

- Technologia uszczelniania napędów elektrycznych zapewnia niezawodność swojego działania.

Inne rozwiązania e-mobility

Odkryj inne rozwiązania, które MD Polonia oferuje dla branży E-Mobility.

E-Mobility PDF documentation

Download or view the E-mobility documentation offered by MD Poland, Enjoy your reading.