Wyzwania E-Mobility dla systemów ADAS

Wraz z wprowadzeniem innowacyjnych pojazdów, przemysł motoryzacyjny zmienia się szybko, w rezultacie stając się transportem bezpieczniejszym i wydajniejszym. ADAS, Advanced Driver Assistance Systems, są to kluczowe elementy nowej generacji mobilności, bezpieczeństwa i łączności. Obejmują one szeroką gamę czujników, kamer i funkcji łączności. MD Polonia jest liderem na rynku w opracowywaniu zaawansowanych materiałów na potrzeby komponentów w e-mobility.

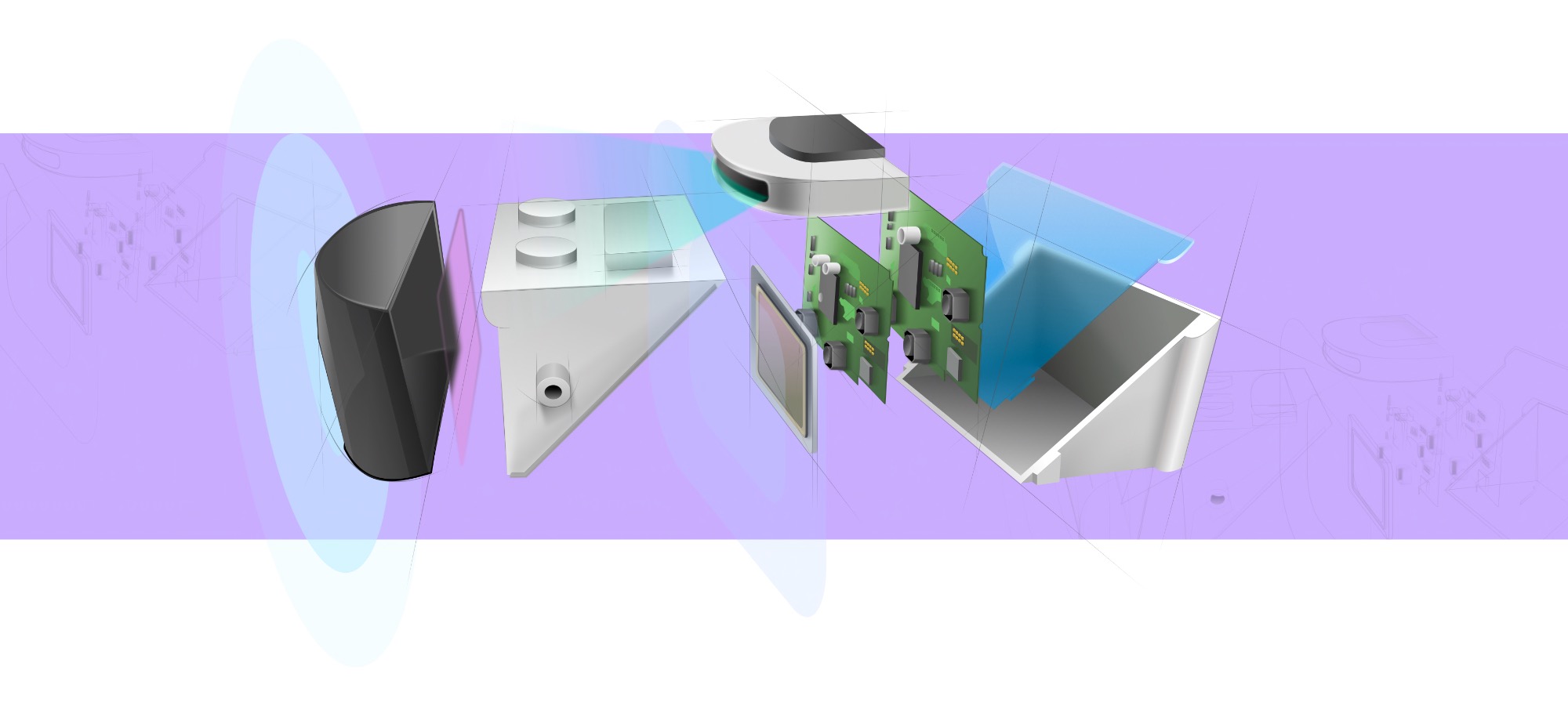

Dzisiaj możemy spotkać na naszych drogach pojazdy półautonomiczne, a pojazdy w pełni autonomiczne niebawem staną się rzeczywistością. Prawdopodobnie zastosowanie ADAS, w najbliższych latach, gwałtownie wzrośnie w miarę rozprzestrzeniania się w przemyśle motoryzacyjnym. Nowe technologie mają za zadanie zapewnienie bezpieczeństwa za kierownicą. Rozwiązania proponowane przez MD Polonia:

- Kleje do szczeliw silikonowych

- Kleje termoprzewodzące do elektroniki

- Conformal coating

- Żele

Łączność

W centrum każdego samochodu wyposażonego w ADAS lub pojazdu samodzielnego, moduł danych łączy informacje otrzymane z różnych czujników, przetwarzając je w dużą ilość konkretnych danych. Odpowiada on za przetworzenie danych obrazowych, radarowych i ultradźwiękowych oraz za wyświetlenie ich na interfejsie użytkownika.

Co więcej, zdolność łączenia się tego systemu ze światem wpłynie na przemysł motoryzacyjny, czyniąc nasze drogi bezpieczniejszymi, a transport bardziej wydajnym. Bezbłędne działanie systemu łączności ma kluczowe znaczenie dla całego systemu ADAS.

Conformal coating

Farba ochronna, inaczej zwana conformal coating, jest cienką warstwą polimeru aplikowaną na płytkę drukowaną (PCB) w celu ochrony płytki i jej elementów przed negatywnym wpływem środowiska oraz w celu zapobiegania korozji.

Kleje do szczeliw silikonowych

Jednoskładnikowe i dwuskładnikowe kleje silikonowe, dzięki swojej elastyczności, absorbują wstrząsy mechaniczne spowodowane naprężeniami dynamicznymi oraz kompensują rozszerzalność cieplną pomiędzy różnymi podłożami. Kleje te tworzą także elastyczne i wytrzymałe połączenia w ekstremalnych warunkach temperaturowych.

Kleje termoprzewodzące do elektroniki

Charakteryzują się one doskonałymi właściwościami dielektrycznymi, odpornością na czynniki atmosferyczne, stabilnością w zróżnicowanym zakresie temperatur, dobrą przyczepnością do zróżnicowanej gamy podłoży, stosunkowo mniejszym obciążeniem komponentów, odpornością na promieniowanie UV oraz na środki chemiczne. Są to idealne produkty do wykorzystania w modułach, złączach, czujnikach, płytkach drukowanych i wielu innych.

Inne rozwiązania z zakresu e-mobilności

Odkryj inne rozwiązania, które MD Polonia oferuje dla branży E-Mobility.

E-Mobility PDF documentation

Download or view the E-mobility documentation offered by MD Poland, Enjoy your reading.