Wyzwania dla energoelektroniki i systemów konwersji EV

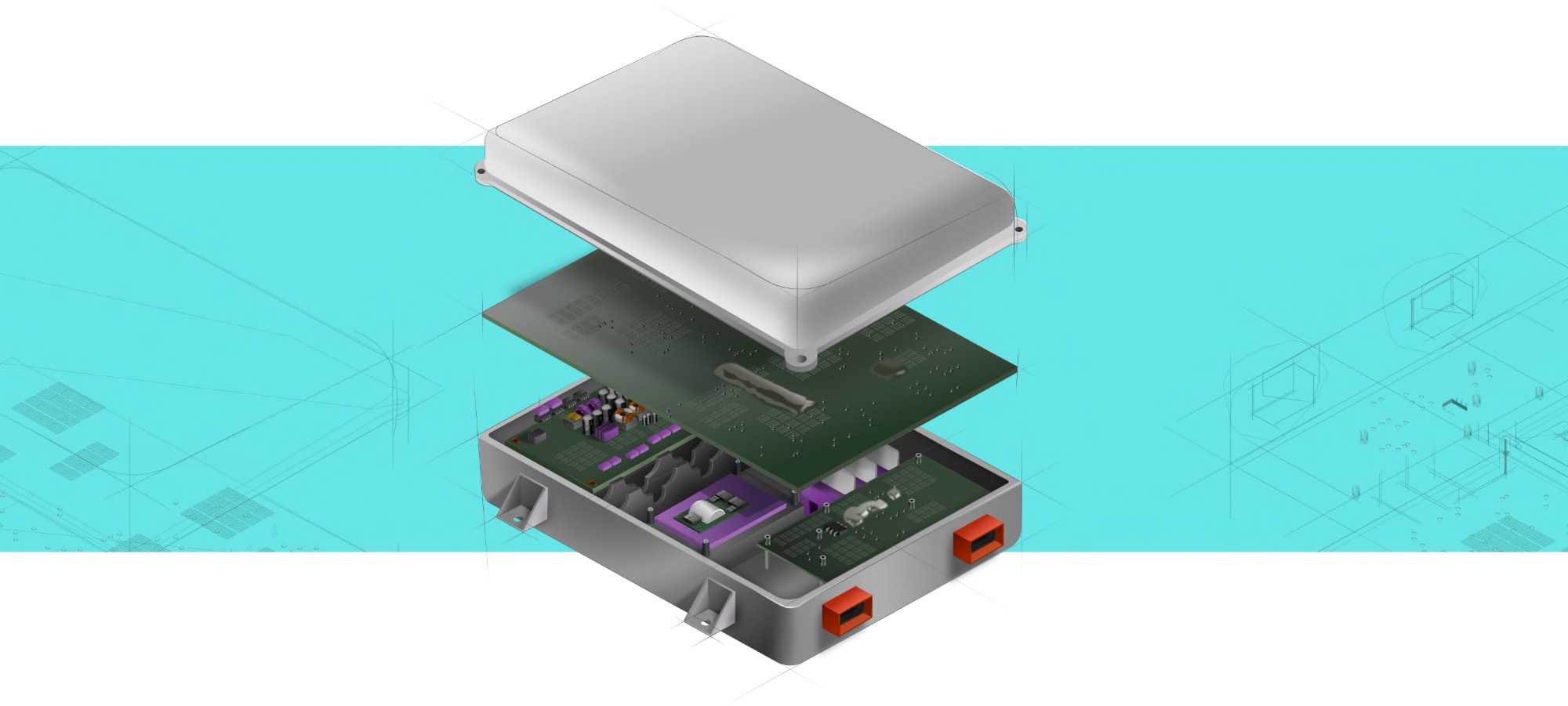

Szereg wyzwań technicznych stanowią trzy systemy konwersji energii: wbudowana ładowarka (OBC), falownik oraz konwerter (DC/DC). Zmniejszenie rozmiarów tych komponentów oraz konsolidacja inwerterów/przetworników z ładowarkami pokładowymi są kluczowe dla niezawodności i bezpiecznej pracy. Odporność na wstrząsy i wibracje, odpowiedzialność środowiska oraz odporność na siły zewnętrzne i wewnętrzne wpływają na osiągi pojazdu. Rozwiązania, jakimi dysponuje MD Polonia:

- Smary do złączy

- Thermal potting

- Gap filler

- Thermal paste

- Conformal coating

- Gasketing

Zarządzanie termiczne

Zminiaturyzowanie części energoelektroniki, m. in. ładowarek oraz ich integracji z innymi systemami EV (przetwornice AC/CD oraz DC/DC) pomaga producentom zaoszczędzić przestrzeń. W przypadku mniejszych komponentów, powierzchnia dostępna do działania jako radiator jest także mniejsza, mimo większej gęstości mocy. W rezultacie, urządzenia o wyższym napięciu, stwarzają ekstremalne wyzwania pod względem bezpieczeństwa pracy i ładowania, zwłaszcza w przypadku przejścia na szybkie ładowanie. Asortyment materiałów termoprzewodzących, jaki oferuje firma MD Polonia, np. gap fillers, gap pads czy kleje termoprzewodzące, zostały specjalnie zaprojektowane z myślą o wymaganiach w innowacji dotyczących pojazdów elektrycznych.

Niezawodność

Przetwornice AC/DC, DC/DC oraz ładowarki pokładowe muszą wytrzymać w trudnych warunkach oraz sprostać zróżnicowanym obciążeniom mechanicznym. Odporność na wstrząsy i wibracje podczas eksploatacji pojazdu mają kluczowe znaczenie dla bezpiecznej i niezawodnej konwersji mocy, a także w celu ochrony elektroniki przed czynnikami chemicznymi i środowiskowymi. Technologie firmy MD Polonia, dzięki różnorodnym technologiom uszczelniania oraz materiałom zapewniającym ciepło, w tym hermetyzacji termicznej do rozpraszania ciepła, mają ma celu poprawienie trwałości i niezawodności każdego z elementów konwersji energii.

Conformal coating

Farba ochronna, inaczej zwana conformal coating, jest cienką warstwą polimeru aplikowaną na płytkę drukowaną (PCB) w celu ochrony płytki i jej elementów przed negatywnym wpływem środowiska oraz w celu zapobiegania korozji.

Gasketing

Technologie uszczelniania część elektronicznych chronią prze płynami samochodowymi i innymi czynnikami zewnętrznymi.

Gap Filler

Materiał jest najpierw nakładany w postaci cieczy na docelową powierzchnię, następnie, gdy elementy są już zmontowane, zamacza się w sąsiednich powierzchniach, wypełniając najmniejsze powierzchnie i szczeliny powietrzne.

Thermal potting

Enkapsulanty mają za zadanie chronić delikatne elementy elektroniczne w silniku elektrycznym przed wibracjami, wysokimi temperaturami, kurzem, korozją i wilgocią.

Inne rozwiązania z zakresu e-mobilności

Odkryj inne rozwiązania, które MD Polonia oferuje dla branży E-Mobility.

E-Mobility PDF documentation

Download or view the E-mobility documentation offered by MD Poland, Enjoy your reading.