Wyzwania oświetlenia

Produkty firmy MD Poland mogą być wykorzystywane do tworzenia systemów ochronnych LED w środowiskach o zróżnicowanych warunkach pracy, w tym przy instalacjach oświetleniowych w środowiskach korozyjnych lub zanieczyszczających środowisko.

MD Poland dysponuje także produktami, które wpłyną na estetykę całego systemu oświetleniowego, a także pomogą zoptymalizować wydajność danego systemu, w tym zmniejszenie zużycia energii oraz zwiększenie wydajności.

W zależności od środowiska, w którym używane są diody LED oraz powiązane z nimi komponenty, należy dobrać odpowiednie produkty do ochrony systemu i zapewnienia większej wydajności.

Przykładowo, jeśli warunki pracy systemu oświetleniowego przewidują wysoką wilgotność, obecność środków chemicznych, mgły solnej lub ryzyka korozji, MD Poland pomoże dobrać odpowiednie materiały, które przyczynią się do ochrony systemu przez cały okres eksploatacji całego systemu.

Dzięki szerokiej gamie produktów, MD Poland może zaoferować materiały odpowiednio dobrane pod kątem aplikacji LED, np. niski lub zerowy poziom LZO.

Oszczędność energii jest jednym z ważniejszych celi w dzisiejszej cywilizacji konsumpcji. Producenci systemów oświetleń, coraz bardziej skupiają się na tym, aby ich systemy zużywały jak najmniej energii jednocześnie wydłużając żywotność i wydajność urządzeń. MD Poland oferuje produkty montażowe, termoizolatory, materiały termoprzewodzące, kleje i uszczelniacze oraz powłoki konforemne. Jeśli Twoja aplikacja obejmuje produkcję, montaż, ochronę lub ulepszanie systemów oświetleniowych LED, MD Poland pomoże Ci znaleźć rozwiązania dopasowane do Twoich potrzeb związanych z doborem materiałów oraz zastosowaniem naszych produktów.

Ochrona i montaż

- Kleje i uszczelniacze

- Enkapsulanty optyczne

- Powłoka ochronna

- Osłony termiczne

- Materiały termoprzewodzące

Silikony optyczne

- Optyka do formowania

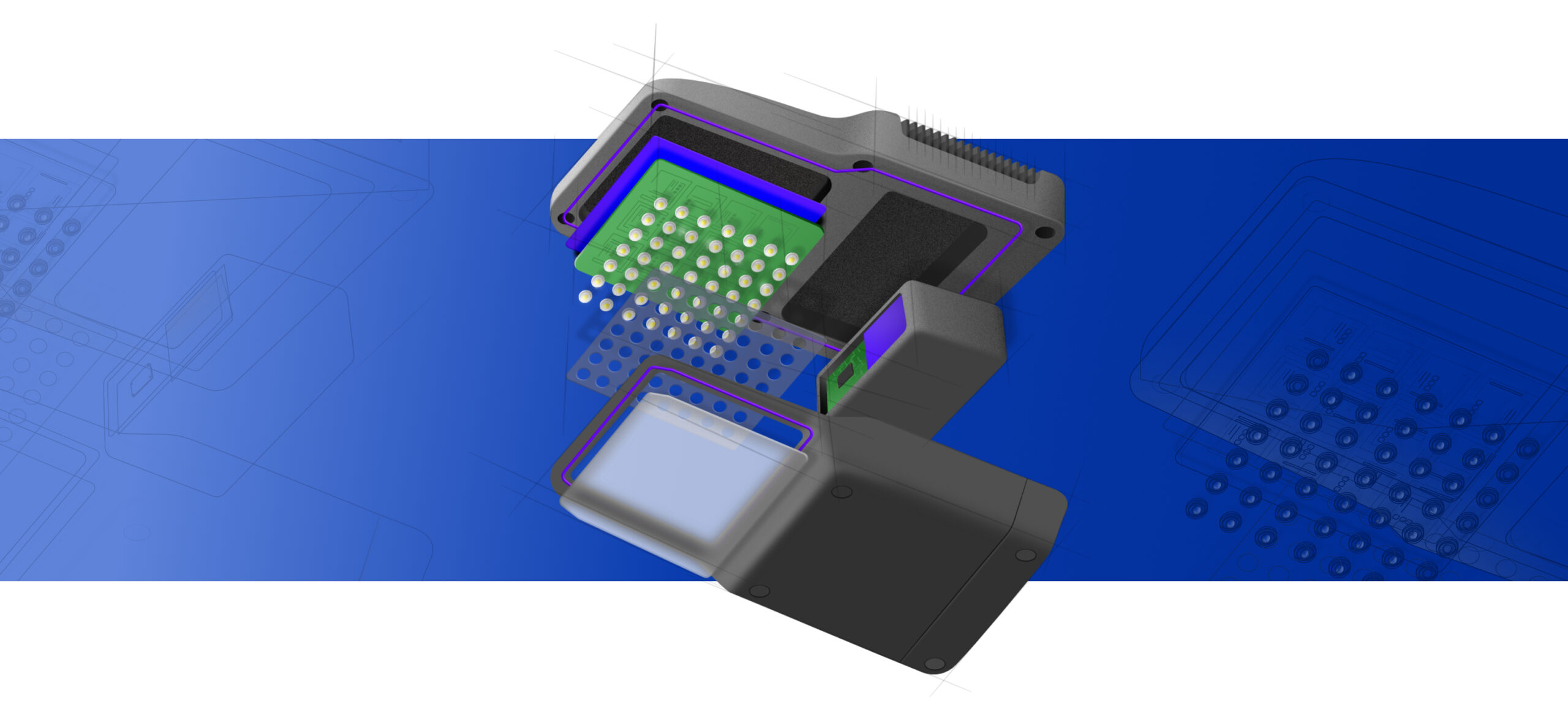

Oświetlenie ledowe

MD Poland wykorzystuje produkty zróżnicowane pod względem składu. Odkryj zastosowania dedykowane oświetleniu LED.

Uszczelniacze dla ochrony elektroniki

Przewodzące ciepło kleje oraz uszczelniacze silikonowe doskonale nadają się do połączenia i uszczelniania z różnymi podłożami powszechnie stosowanymi w lampach i oprawach LED. Gwarantują nam one niezawodną i długotrwałą wydajność nawet w temperaturach powyżej 120°C.

Enkapsulanty

Nasze silikonowe osłony przewodzące ciepło o wysokim stężeniu chronią sterowniki LED przed wilgocią oraz kurzem, jednocześnie rozpraszając szkodliwe ciepło i pochłaniając wytwarzające się podczas pracy dźwięki.

Przewodniki ciepła

Nasza szeroka oferta materiałów przewodzących ciepło pozwala na wszechstronne zarządzanie ciepłem w przypadku każdej lampy LED i każdego projektu jej oprawy.

Powłoka ochronna

Nasze silikonowe powłoki ochronne chronią system elektroniki połączony z diodami LED przed wilgocią i zmianami temperatury. Zapewniają także izolację przed wysokimi napięciami i zwarciami.

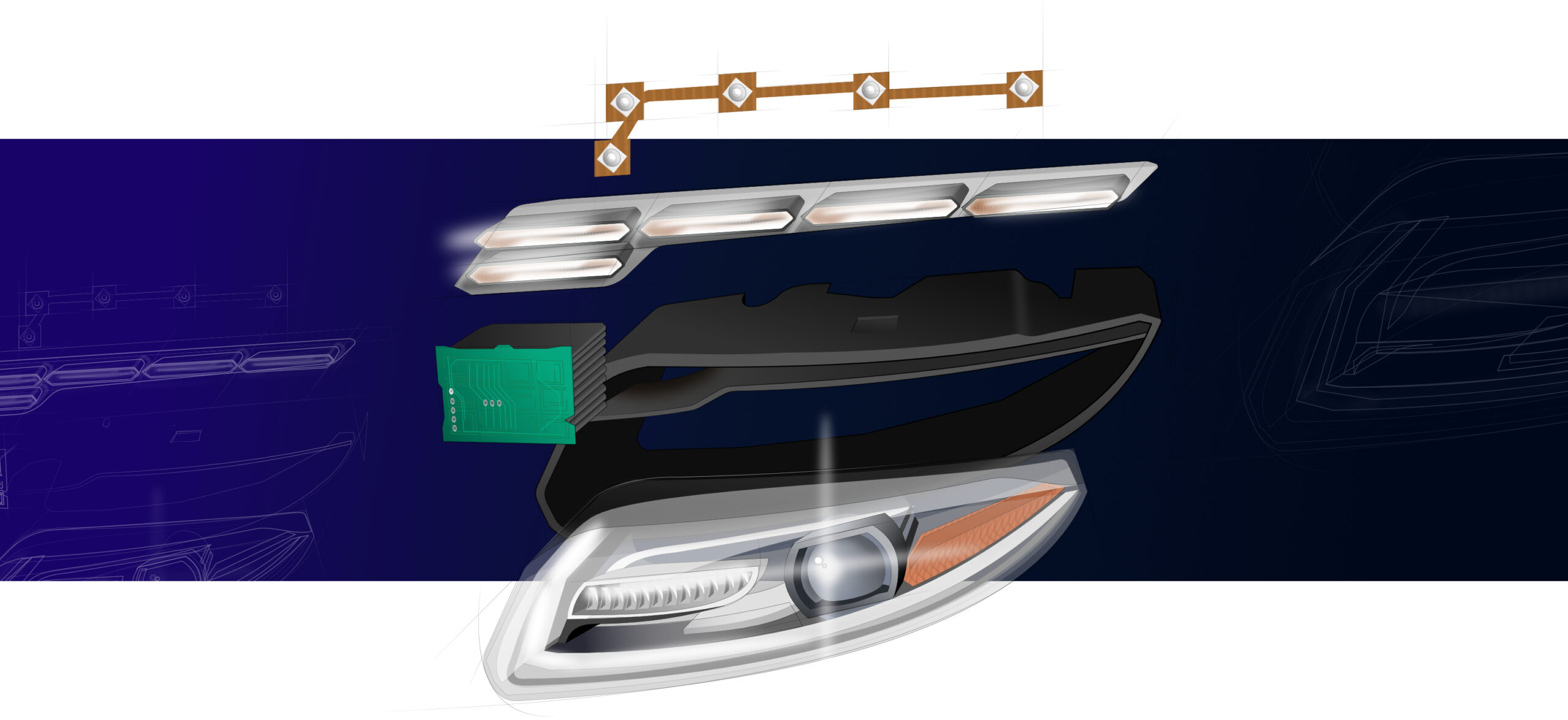

czołówki LED

Poznaj zastosowanie produktów chemicznych opracowanych przez MD Poland w czołówkach LED.

Uszczelniacze dla ochrony elektroniki

Przewodzące ciepło kleje oraz uszczelniacze silikonowe doskonale nadają się do połączenia i uszczelniania z różnymi podłożami powszechnie stosowanymi w lampach i oprawach LED. Gwarantują nam one niezawodną i długotrwałą wydajność nawet w temperaturach powyżej 120°C.

Enkapsulanty

Nasze silikonowe osłony przewodzące ciepło o wysokim stężeniu chronią sterowniki LED przed wilgocią oraz kurzem, jednocześnie rozpraszając szkodliwe ciepło i pochłaniając wytwarzające się podczas pracy dźwięki.

Przewodniki ciepła

Nasza szeroka oferta materiałów przewodzących ciepło pozwala na wszechstronne zarządzanie ciepłem w przypadku każdej lampy LED i każdego projektu jej oprawy.

Powłoka ochronna

Nasze silikonowe powłoki ochronne chronią system elektroniki połączony z diodami LED przed wilgocią i zmianami temperatury. Zapewniają także izolację przed wysokimi napięciami i zwarciami.

Ochrona i montaż

Kleje i uszczelniacze

Za pomocą tworzenia trwałych i nieobciążających naprężęń elastomerów, silikonowe kleje i uszczelniacze oferowane przez MD Poland, pozwalają na doskonałe łączenie i uszczelnianie pomiędzy różnymi popularnymi materiałami do oświetlania LED. Materiały niezawierające rozpuszczalników, polimeryzują się w temperaturze pokojowej, dzięki czemu przetwarzanie jest uproszczone, a niska lotność pozwala na utrzymanie strumienia świetlnego przez cały okres użytkowania.

Enkapsulanty optyczne

Zużycie żywicy hermetycznej do ochrony diod LED staje się coraz bardziej popularne w ostatnich latach. Jej wybór zależy od kilku czynników: lepkości, żywotności, czasu żelowania, twardości, gęstości oraz temperatury roboczej utwardzonej żywicy. Jednym z najważniejszych czynników w bezpośredniej ochronie diody LED jest przezroczystość zastosowanego materiału. Ważne jest, żeby zapewnić maksymalne wykorzystanie światła emitowanego przez diodę. Należy wziąć także pod uwagę wszelkie zmiany, które mogą wystąpić podczas eksploatacji diody LED.

Powłoka ochronna

Delikatne elementy elektroniczne wchodzące w skład Twojego projektu muszą być chronione przed wilgocią i czynnikami zewnętrznymi. Nasze silikonowe powłoki ochronne chronią system elektroniki połączony z diodami LED przed wilgocią oraz zmianami temperatury. Zapewniają także izolację przed wysokimi napięciami i zwarciami.

Osłony termiczne

Ochrona i wydajność idą w parze, osłony termiczne MD Poland zadbają o równowagę obydwu tych czynników. Poza odpornością na wilgoć, osłony termiczne, pochłoną także naprężenia cykli termicznych, dzięki czemu wrażliwe elementy będą lepiej chronione. Dzięki wysokiej przepuszczalności i stabilności termicznej, jakość światła w systemie zostanie zachowana przez dłuższy czas, a skład chemiczny zagwarantuje żółknięcie oraz degradacje na najniższym poziomie.

Odpowiednio dobrany profil polimeryzacji, lepkości i twardości pozwoli na opracowanie różnych zastosowań danego projektu. Enkapsulanty MD Poland poszerzają także wachlarz ich zastosowań, od materiałów do dozowania po możliwości tworzenia soczewek z nadrukiem.

Materiały termoprzewodzące

Główną przyczyną skracania żywotności oświetlenia LED jest ciepło, a diody generują go bardzo dużo. Używając silikonowych materiałów przewodzących do produkcji, zwiększają się możliwości zarządzania ciepłem.

Stabilność termiczna silikonów zapewnia stałą i trwałą przewodność cieplną, nawet w temperaturach, w których inne materiały ulegają degradacji.

Kleje termiczne tworzą stabilne termicznie wiązania z większością płytek drukowanych LED i substratami pochłaniającymi ciepło. Zapewniają także doskonałą przewodność cieplną. Ich niska lotność nie wpływa niekorzystnie na poszczególne elementy układu ani na strumień świetlny. Dodatkowo ich właściwości uszczelniające i klejące pozwalają zminimalizować ilość komponentów i zoptymalizować proces produkcyjny.

Silikony optyczne

Formowalna optyka

Formowalna optyka silikonowa firmy MD Poland oferuje niespotykany dotąd poziom swobody projektowania. Materiały, które dają się formować, pozwalają na tworzenie bardziej złożonych projektów, zarazem upraszczając proces produkcyjny.

Ponadto mogą się przyczynić do wydłużenia wydajności projektu dzięki zastosowaniu nowoczesnych technologii. Poza doskonałymi właściwościami optycznymi są także odporne na uderzenia oraz degradację spowodowaną promieniami UV, ciepła lub trudnymi warunkami środowiska. Optyka silikonowa zapewni wyższą gęstość światła jednocześnie zachowując jego stabilność.

Dzięki nadającej się do formowania optyce silikonowej możliwe jest odkrywanie nowych możliwości projektowych w złożonych systemach takich jak oświetlenie samochodowe, wyświetlacze zewnętrzne, oświetlenie ogólne, profesjonalne czy konsumenckie.

Motoryzacja

większa mobilność i zaangażowanie w efektywność energetyczną i ochronę środowiska.

Żywność

Przepisy regulujące produkcję żywności stają się z dnia na dzień coraz bardziej surowe i restrykcyjne.

Energetyka

Dystrybuujemy szeroką gamę klejów i uszczelniaczy specjalnie opracowanych do produkcji energii alternatywnej.

Elektronika

Elektronika coraz częściej wkracza w nasze życie codzienne, w domu, w samochodzie, w pracy, w rozrywce itp.

Koleje

Dla stare rosnącego zapotrzebowania na lepszą mobilność i efektywność w zużyciu energii.

E-mobilność

Rozwiązania technologiczne, które napędzają nową generację pojazdów hybrydowych i elektrycznych.